The Importance of the Cold Chain in the Pharma Industry

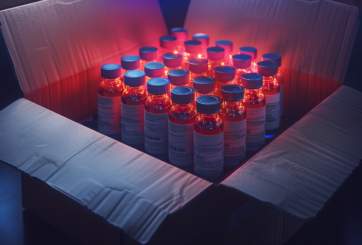

There are multiple types of medication that need incredibly cold temperatures throughout their entire lifecycle, from production, to storage, and from shipping right through to final patient usage.

Without these specific temperatures, the drug can easily lose its potency, or its ability to protect against the very disease it is intended for. Once a vaccine loses its potency, it cannot be regained or restored – which will therefore be a complete waste of time for the patient, and potentially even harmful for them. This is in addition to costing the manufacturer a considerable amount of wasted time, resources and money.

It is therefore vital to ensure these products are kept at the correct temperature, at all stages of their life cycle, a task which relies on a watertight pharmaceutical cold chain.

How does cold chain management of pharmaceutical products work?

The requirement for a watertight cold chain is a topic that advanco has explored extensively, with our findings often reported in some of the pharmaceutical sector’s leading media outlets.

We also covered the topic in a blog last year which references how the cold chain is continuously undergoing evolution as a result of new technological advances.

There are several essential components that are needed to ensure the pharmaceutical cold chain works effectively.

- Manufacturing: The product will need to be kept at the specified temperature during all stages of the manufacturing process. This will often involve the need for all raw components to be kept at a specific temperature.

- Storage:

- Refrigeration: Products are often stored in refrigerators or cold rooms to maintain the required temperature range.

- Monitoring: Continuous temperature monitoring systems are used to track and record temperatures, with alarms to alert personnel if the temperature exceeds acceptable limits.

- Warehousing: Cold chain products are stored in specialized warehouses with strict control over temperature and humidity. Proper organization, labelling, and rotation are critical to prevent product spoilage.

- Transportation:

- Refrigerated Vehicles: These include refrigerated trucks, vans, and trailers designed to maintain consistent temperatures during transport. Depending on the products, dry ice or liquid nitrogen may also be used.

- Packaging: Cold chain products are shipped in insulated containers with temperature-control materials like gel packs, phase change materials, or specialized cooling systems.

- Monitoring in Transit: Data loggers or GPS-based systems track temperature conditions throughout the journey, ensuring products remain within specified ranges. Any deviations from the required temperature range can trigger an investigation.

- Distribution:

- Wholesalers and Distributors: Specialized pharmaceutical distributors manage cold chain products through temperature-controlled facilities and transportation systems, ensuring they maintain quality until they reach healthcare providers or pharmacies.

- Point of Use: Hospitals, clinics, and pharmacies maintain storage systems, including refrigerators and freezers, to keep products within specified conditions until use.

The importance of the cold chain in the pharmaceutical industry.

Without an effective cold chain, many different types of lifesaving and life-enhancing drugs would be useless. This could potentially result in millions of deaths across the globe.

This is a fact that has not gone unrecognised by the regulatory authorities. The FDA (Food and Drug Administration), EMA (European Medicines Agency), and WHO (World Health Organization) impose stringent guidelines for the storage, transportation, and handling of temperature-sensitive pharmaceuticals. Compliance with these regulations ensures product quality and reduces the risk of recalls, liability, or penalties.

Furthermore, cold chain management also supports Good Distribution Practice (GDP) standards, ensuring that the pharmaceutical supply chain remains reliable and traceable from production to end-user.

Advanco’s own data also underlines the growing importance of the cold chain, with a substantial year on year increase recorded over many consecutive years. Advanco’s ARC Cold Chain enables easy management, maintains compliance, and utilizes historical data to optimize all essential cold chain processes. It is a pioneering solution within the cold chain industry, able to capture temperature variations and data quickly and efficiently in packaging, refrigerated trucks, and cooling rooms.

What has been the positive impact of cold chain management in the pharmaceutical industry?

Cold chain management has had a profound positive impact on the pharmaceutical industry in multiple ways, improving the safety, effectiveness, and accessibility of temperature-sensitive drugs and vaccines.

- Improved Drug and Vaccine Efficacy

By preserving drugs in optimal conditions, cold chain management prevents degradation, which is especially critical for treatments that require precise storage, like mRNA vaccines (e.g., COVID-19 vaccines) and certain cancer therapies.

- Expanded Access to Life-Saving Treatments

Cold chain logistics enable the global distribution of temperature-sensitive drugs, allowing them to reach patients in remote and underdeveloped regions. The development and deployment of efficient cold chains have expanded access to immunization programs, improving public health worldwide. For example, polio, measles, and COVID-19 vaccines have reached millions of people globally, contributing to the reduction of disease prevalence and mortality.

- Reduced Drug and Vaccine Wastage

Proper cold chain management reduces the risk of temperature excursions, which can render drugs unusable. By minimizing spoilage, the pharmaceutical industry has been able to significantly reduce waste, resulting in cost savings and greater product availability. This also helps sustainability in the cold chain – a topic which advanco has explored previously.

- Increased Safety for Patients

Cold chain management ensures that drugs are stored and transported under conditions that prevent spoilage or contamination. This ensures patients receive safe and effective medications, reducing the risk of adverse reactions due to compromised products.

- Compliance with Regulatory Standards

Cold chain management helps pharmaceutical companies meet stringent regulatory requirements set by agencies like the FDA, EMA, and WHO, ensuring that products maintain their quality from manufacturing to end-use. Compliance with these standards not only guarantees the safety and efficacy of products but also prevents costly product recalls, legal issues, and damage to company reputations.

What role did cold chain management play in the Covid-19 pandemic?

Cold chain management played a critical role in the global response to the COVID-19 pandemic, particularly in the distribution of vaccines, ensuring that vaccines maintained their efficacy, safety, and stability from production to administration.

The rapid deployment of temperature-sensitive vaccines, such as those based on mRNA technology, required precise cold chain logistics.

The mRNA vaccines, such as those developed by Pfizer-BioNTech and Moderna, were among the first COVID-19 vaccines to receive emergency use authorization, but they required ultra-cold storage to remain stable. Pfizer-BioNTech’s vaccine needed to be stored at around -70°C (-94°F), while Moderna’s vaccine required storage at -20°C (-4°F).

The stringent temperature requirements necessitated advanced cold chain infrastructure, including ultra-low temperature freezers, specialized insulated containers, and dry ice for long-haul shipments. Cold chain management was essential for safely delivering these vaccines to countries, regions, and communities worldwide, ensuring their stability during transit.

The cold chain also enabled the rapid, mass-scale distribution of COVID-19 vaccines across the globe. This was especially challenging given the unprecedented speed and scale at which vaccines needed to be distributed to curb the spread of the virus.

Without the cold chain, the efficacy of the vaccines would have also been called into question, along with many other aspects of the roll out.

Conclusion

The pharmaceutical cold chain is now established as an essential, core component of the overall pharma sector.

Without it, people would suffer on a giant scale, and the world would be thrown into a public health crisis. It is therefore essential that the cold chain continues to be the topic of extensive research and development to ensure it is functioning at its maximum potential – for the good of the entire globe.

VIEW THE ORIGINAL ARTICLE HERE