Leaders in cross-industry serialization

Regulatory compliance for serialisation is increasingly becoming a focus area for pharmaceutical manufacturers and supply chain partners across the world. Therefore, as would be expected, advanco is already well-known and solidly established within the pharmaceutical sector.

Regulatory compliance for serialisation is increasingly becoming a focus area for pharmaceutical manufacturers and supply chain partners across the world. Therefore, as would be expected, advanco is already well-known and solidly established within the pharmaceutical sector.

However, this could be just the beginning, with a very real potential for such services across multiple other consumer and business sectors.

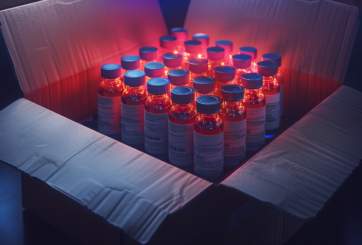

Staying with pharma for the moment, most developed and developing economies have either already laid out the regulatory road map for serialisation or are in the process of doing so. This is largely due to rising drug-related criminal activities and supply chain inefficiencies. Certainly, pharmaceutical counterfeiting is a profoundly serious issue, one which is likely to worsen as the world searches for a COVID-19 cure. It is estimated that 10% of pharmaceutical products worldwide are counterfeit, resulting in up to one million deaths every year, and British researchers have estimated counterfeit medication could kill up to 10 million people by the year 2050. In addition, the global counterfeit drug market size exceeds $75 billion.

To help with this, advanco is focusing on product identification in the supply chain, using barcode technologies to prevent counterfeits in pharmaceuticals. This core expertise in barcode, RFID and supply chain solutions has been informed by 41 years of experience.

Advanco has concentrated on customers in the pharmaceutical industry for over 11 years, with its first customer being Pfizer Turkey. Throughout this time, it has established itself as a leading provider (ISV) for Level 3 Item Level Serialisation and Trackand-Trace throughout the entire supply chain and around any ERP system.

Advanco’s ARC, a serialisation packaging solution for Track-and-Trace, is the gateway to the national databases used for verification. ARC is used by over 40 customers around the globe at more than 50 sites, controlling over 400 package lines.

The entire solution is built to and complies with strict international regulatory standards and ensures companies comply with global legislation (such as EU Hub, MDLP, Turkish MoH), including all special functionalities like Russian Cryptocode or US DSCSA requirements on the shop floor and in the warehouse.

ARC has the largest interface portfolio in the industry and is designed to prevent counterfeits in the pharmaceutical industry by focusing on product identification in the supply chain. Integrating packaging lines and enterprise serialisation repositories, it is created for companies to utilise multiple line management systems, simplify integration and enhance flexibility, and it can adapt to a wide range of packaging line technologies and production management systems.

What’s more, integration across control and enterprise levels enables ARC to function as a centralised hub for managing serialisation data and facilitating product traceability across the entire supply chain.

Advanco also has a solution portfolio for Serialization 2.0., from compliance to optimization. Replacement of components, lowering the TCO, OEE and blockchain are all part of Serialization 2.0

A noteworthy development for the company, advanco recently announced a ground-breaking partnership with former Bosch packaging giant Syntegon. This partnership is already seen as being of great importance to the overall pharmaceutical serialisation sector, opening-up the rigid nature of the serialisation track & trace supply chain.

It combines the strength of advanco’s leading software site manager system, known as ARC, which handles the serialisation and aggregation processes, with Syntegon’s high-end machines for packaging pharmaceutical products and drugs. This development will bring tremendous value to pharmaceutical companies by significantly lowering the total overall cost and preventing a lock-in effect, allowing vendors to choose different machines from different suppliers.

View the original article here.